Venturi Automobiles (Principality of Monaco) is famous for its advanced electric vehicle technologies with each car being an incredible feat of engineering. In 2008 at the Motor Show in Paris Venturi revealed a very peculiar concept — the all-electric coupé Volage.

DID YOU KNOW THAT...

... Venturi Automobiles was founded by Claude Poiraud and Gérard Godefro in 1984 in Fontvieille, Monaco. The company designs, produces and sells luxury electric cars. Venturi’s division in North America (based in Columbus, Ohio) is a research and development centre while the company’s subsidiary is a motorcycle manufacturer Voxan.

The company’s first car Venturi 300 Atlantique was produced in 1984. This French Grand Tourismo car was created to compete with the French Bugatti, Italian Ferrari, and German Porsche.

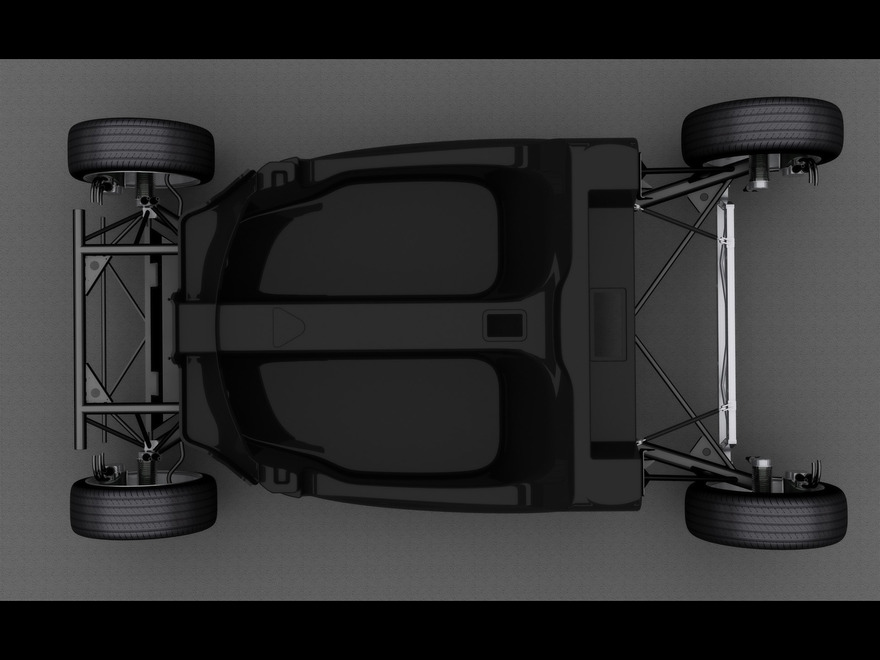

The hallmark of Venturi’s supercar lies in its engineering idea — the concept lacks engine and transmission in the usual sense. The weight of Volage is really small — just 1,075 kg. It has carbon sandwich/aluminium honeycomb chassis with front and rear mesh made of aeronautic steel. The only elements found inside the bodyshell are liquid-cooled lithium-ion Zebra-batteries (weight of batteries is 350 kg) and a cockpit for two people.

“Just how is this car powered?” might be your next question. And here is the answer — all its motors are inside the car’s wheels! Venturi used Michelin’s know-how in its unique supercar — the “Active Wheel” technology.

The main point of Active Wheel lies in the fact that apart from braking mechanism each wheel is fitted with active suspension and a compact package with two electric motors — one for propulsion and another one for the work of suspension.

The basis of Active Wheel is a lightweight aluminium frame connected with the help of a simple rigid lever to the body subframe. This connection is moveable so that the wheel could turn. The rim is secured to a flat disk-shaped hub. All Active Wheel components are attached to the inner part of the frame. The braking mechanism comprises rotating disc and callipers with electromagnetic actuators. The traction motor works in a generator mode while braking — it produces electricity to power the onboard battery. Suspension consists of a steel spring and electric shock absorbers. The motor which controls shock absorbers is also responsible for turning the wheel.

Advantages of vehicles with in-wheel motors over traditional vehicles:

— lack of numerous sophisticated and heavy gear mechanisms between the motor and the wheel — clutch, transmission, drive shafts and differentials;

— excellent dynamics — compact and lightweight electric motors are capable of developing torque up to 700 Nm even at very low revs;

— great manoeuvre capability — all wheels can rotate at different speeds and in different directions. The car can make a 360 degree turn, park in the most difficult conditions and adapt instantly to various types of road surfaces;

— the entire construction of braking energy recovery system is much more simplified;

— securing active road safety — all modern systems like the ABS, ESP, Traction Control, Brake Assist and so on provide electronically-controlled influence upon each wheel individually.

Disadvantages:

— plenty of mechanisms placed inside the rim;

— the reducing gear should be compact and leakproof — it really increases the weight of the wheel. Big unsprung weight (meaning heavy wheels) sharply reduces the comfort and controllability, increases the wear of suspension, transmits additional vibration to the body.

— Repair of such wheels requires high qualification. You will not be able to change tyres in a regular tyre repair centre and a spare wheel might cost quite a lot if you decide to purchase a few wheels just to be on the safe side.

But Michelin engineers assure potential customers that maintenance, repair and tyre change of Active Wheels wouldn't cause any trouble. The tyre is dismountable together with the rim of the wheel. However, the effects of low temperatures, dirt and water to Active Wheel have not been precisely studied yet.

So, in fact, Volage is equipped with eight engines — two for each of four wheels. Mass of one of leading motors intended for this Venturi concept is only 7 kg with maximum power of 75 hp and torque of 58 Nm produced in the range from 0 to 8,500 revolutions per minute. The weight of the rest of the elements fitted inside the active wheel is only 11 kg.

The electric motor inside one wheel has the maximum power of 55 kW which gives the total of 220 kW or 300 hp at the maximum torque of 232 Nm (0–8,500 rpm). According to the calculations made by the engineers, the efficiency factor of such powerplant is 90 percent.

The unique construction of Volage makes it possible to accelerate from 0 to 100 km/h in approximately 4.9 seconds. The manufacturer published the following data: 0-to-50 km/h sprint in 2.2 seconds. But then again the top speed of this unique vehicle is electronically limited at 150 km/h. It has to do with saving battery life.

It will take 4 hours to charge the battery up to 80% with help of external 10-kW recharge booster. In regular charging mode the battery will be fully restored in 8 hours. The car can travel up to 320 km at the speed of 90 km/h with fully charged batteries.

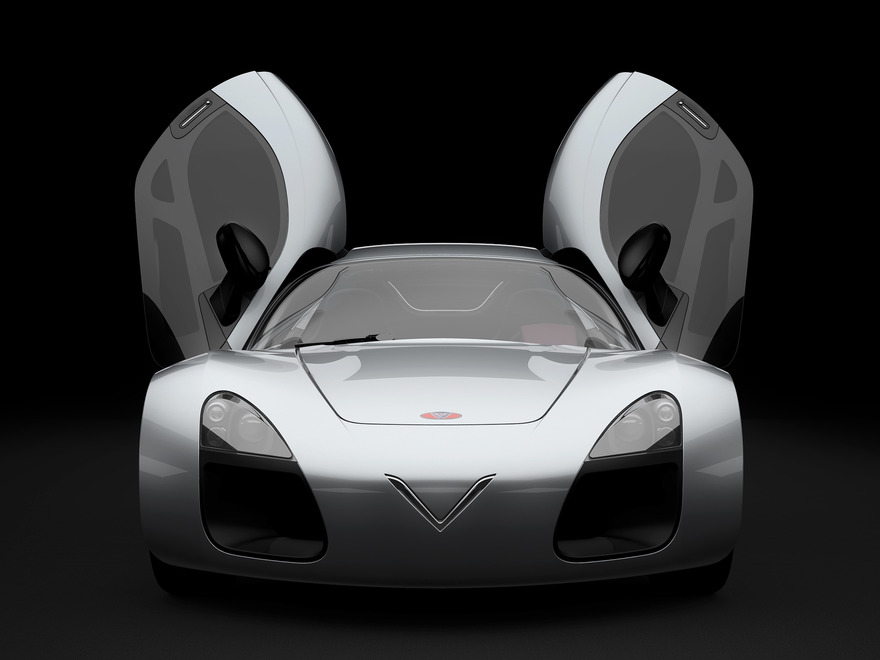

The famous French designer Sacha Lakic, who is considered to be an enfant terrible (a rebel and trouble-maker) in many quarters, gave the following explanation of this concept: “Motors incorporated into the wheels have enabled me to create a very specific design project. I used this technology to work out the general style of the car with the void, which is usually occupied by various mechanical elements, fashioned by the wind”. The design of the concept is truly impressive — futuristic body outline slightly resembling French pre-war retro cars but shaped in full compliance with laws of aerodynamics.

Many mechanical unites were replaced by electronics — thanks to a dashboard touch screen, the driver can control the majority of car’s options. Moreover, Venturi Volage features a great number of adjustments and settings. For instance, the driver might prefer travelling distance over power or additional comfort over speed.

The car’s breakthrough design provides high level of battery safety and ideal weight distribution — 45% at the front, 55% at the rear. Volage adapts easily to various road surfaces and driving styles. According to Michelin engineers, thanks to advanced electronics the response time of electronic suspension is just 0.003 seconds which is much faster than that of a standard hydraulic shock absorber.

Suspension behaviour changes in one-thousandth of a second meaning there is no need to look for a compromise between the travelling comfort and handling characteristics. At the touch of the dashboard display the driver can choose one of several modes of suspension stiffness or the level of steering wheel sharpness. It means that Volage would be a perfect choice for those who would like to point out their individuality as the unique Michelin technology allows adjusting to any driver’s wishes.

But there is one more thing which needs to be mentioned... After unveiling the premiere, Venturi announced its production plans. It was reported that Volage would be assembled by hand in the form of a very limited production — about 10 units per year. First cars had to go on sale in 2012 with their price starting at €297,000. It’s 2014 outside but there has been no word about the Volage yet…